Controlling Insects in Stored Grain

ENTFACT-145: Controlling Insects in Stored Grain | Download PDF

by D.W. Johnson and L.H. Townsend, Extension Entomologists

University of Kentucky College of Agriculture

Over 50% of the grain produced in Kentucky is held in "on-farm" storage for some period of time. In the past this storage was short-term, from harvest until early spring. However, times have changed drastically. Now, storage periods of 12 months or longer are common. As a result, grain remains undisturbed for long intervals, including the high risk, warm, moist months from late spring to early fall.

The primary causes of grain spoilage in Kentucky are excess moisture and high temperature. However, any grain improperly handled or stored longer than 6 months can be infested by insects. The key to successful storage is to anticipate and prevent potential problems through good bin management practices. Preventing insect problems in stored grain requires 3 steps: 1) sanitation, 2) protection and 3) inspection.

SANITATION

Stored grain insect infestations rarely begin in the field. Most develop from small numbers of pests already present in or around farm storage bins. An effective sanitation program can eliminate or greatly reduce the chance of having serious problems with these insects.

Equipment: Grain handling equipment should be kept clean. The effort involved in thorough preparation of storage bins is of little value if they are filled using contaminated equipment. Combines, trucks, augers and grain driers should be thoroughly cleaned of all old grain.

The Empty Bin: Never put newly harvested grain into bins containing old grain. Empty the bins of all residual grain, then use shovels, brooms and industrial vacuums to complete the job. Be especially careful to clear dust, webbing and fines from around any cracks and crevices, doors, seams, vents and especially under false floors. Even small amounts of old grain left in the bins may harbor enough insects to start a problem. Once the bins are clean, inspect them and repair any cracks or holes which would allow moisture or insects to enter. Then, spray the inside completely with an insecticide. (See Insecticides and Fumigants)

Near the Bin: The area immediately surrounding the bins should be kept clean. Be sure to remove and destroy all spilled grain. Control weeds and grasses, since they can harbor insect and rodent pests. Inspect outside walls and especially the base and roof for damage that could allow pests and moisture to enter. Do not use the area immediately surrounding the grain bins to store cattle feed; keep stock feeders as far away as possible.

The Grain: Store only clean, dry grain. A small percentage difference in moisture content can make a big difference in the probability of a damaging insect infestation. The optimum moisture content for stored grain is 12-13%. Most grain inhabiting insects require 13-15% moisture for maximum feeding and reproduction.

It is also advisable to clean grain before binning. Small pieces of dockage and cracked or split grain provide food for insects not normally found in whole grain. Even though most of these insects will not feed on whole grain, their biological processes produce heat and moisture which can greatly reduce the stored grain's quality.

Level the grain surface once the bin has been filled. This will allow for good air flow and thus improved moisture and temperature control. It also will allow improved access for inspection and treatment.

CHEMICAL PROTECTION

In empty bins, apply a coarse spray of an approved insecticide to run-off at least 2 weeks before binning (See Insecticides and Fumigants). Pay close attention to areas which might hide insects, such as under false floors and vents. Cracks around doors and vents may serve as sources of infestation.

A grain "protectant" is an insecticide that can be applied to the bulk grain as it goes into a storage bin (See Insecticides and Fumigants). The treatment offers protection for about one season and should be considered if the grain may be held for more than 6 months. Proper calibration of the application system is important to ensure even insecticide distribution throughout the grain. Protectants are effective against both beetle and caterpillar pests.

A surface dressing (Cap Out) may be applied to prevent insects from entering the top of the grain mass and to control surface infestations of Indian meal moth, when a "protectant" is not used (See Insecticides and Fumigants). Though surface dressing may be useful if a grain protectant is not used, it will not reduce an established infestation within the grain mass. Producers anticipating problems with these pests should follow some specific steps:

Apply the surface dressing as a coarse spray in enough water to obtain adequate coverage. The recommended amount of water differs among products, so check the label of the insecticide you choose. After you spray, incorporate the insecticide into the top 4 inches of grain surface.

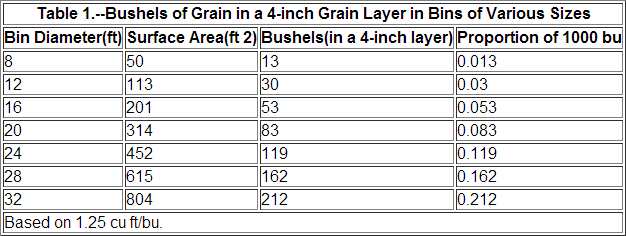

To compute how much insecticide you need for top dressing, select the desired product (See Insecticides and Fumigants) and multiply the recommended use rate (example, 1 pt/1000 bu) by the proportion of 1000 bushels contained in the top 4 inches of your bin. Table 1 lists the proportion of 1000 bu in the top 4 inches of some common sized bins. For example, if you wish to top dress a 24 ft bin with a compound at the rate of 1 pt/1000, then 1 pt. x 0.119 = .119 pt or 1.9 oz.

Infestation in the Grain Bulk

Fumigants are gases that penetrate the grain and kill insects both on and in the grain. They are very toxic to man and animals and should be applied only by trained, experienced operators working in pairs.

Once an insect infestation has become established, there are only two treatment options: (1) move the grain and apply a protectant during transfer or (2) fumigation. Both choices have good and bad points. Application of grain protectants during movement will provide some residual protection. But moving grain is costly, time consuming and requires additional bin space. Also, if good control is not achieved, movement will spread the insects throughout the grain mass. On the other hand, fumigation works very well and is relatively cheap. Fumigants are gases that penetrate the grain and kill insects both on and in the grain. They are very toxic to man and animals and should be applied only by trained, experienced operators working in pairs. But because it is very sensitive to poor technique, many failures occur. Also, it is dangerous and provides no residual protection.

Fumigation

Several factors are important in assuring successful fumigation.

- Grain should always be level in the bin to let the fumigant penetrate evenly.

- Any surface caking or crusting should be broken up and removed.

- Grain temperature should be 60°F or higher to ensure proper vaporization.

- Possible leak points such as cracks or holes in the bin should be closed before fumigation since leakage may result in under treatment and poor control.

Causes of Fumigation Failures

Fumigation failures can usually be attributed to one or more of the following:

- Insufficient fumigant--A fumigant's efficiency depends on its attaining a lethal concentration in the grain. Results will not be satisfactory if less than the recommended dosage is used or if the fumigant is applied under unfavorable conditions.

- Storage structure--Leaky bins will not retain fumigants long enough to kill the insects. The depth of grain also affects a fumigation's efficiency. In general, the greater the surface area of the grain in relation to bulk, the greater the difficulties in adequate fumigation. As a result, flat storage bins require higher dosages than do round silo bins. Also, storage structures with a large amount of space over the grain are difficult to fumigate effectively because large amounts of gas escape into that space.

- Moisture--As moisture content increases above 12% a proportionately higher dosage of fumigant is required. It is difficult to effectively fumigate grain having a surface moisture content of 15 to 20% because the fumigant vapors will not penetrate the moist layer.

- Temperature--During fumigation, the gas quickly assumes the temperature of the grain. In general, fumigant activity increases as temperature increases. However, if grain temperature reaches or exceeds 115 °F, the fumigant may vaporize very rapidly and escape from the bin before accomplishing the job. On the lower end of the spectrum, stored grain insects are inactive at temperatures below 60°F. Fumigation should be delayed until the grain temperature increases.

Treatment

Should fumigation become necessary, a variety of compounds are available for treatment (See Insecticides and Fumigants). Fumigants are inherently dangerous and should be applied only by trained operators. Operators should wear a full face gas mask equipped with the proper canister, and have access to self contained breathing apparatus, and another person should always be present during fumigation.

Refer to the training material developed by the manufacturer.

INSPECTION

Grain bin inspection provides important information on the general condition, temperature, moisture and pest activity of stored grain. Inspections allow early detection of problems and enable corrective action to be taken before damage becomes severe See: "Aeration, Inspection and Sampling of Grain in Storage Bins," Extension publication AEN-45, provides procedures for checking storage facilities.

Using Probe Traps for Insect

The commercially available "probe" traps may be the easiest and safest way to monitor for several beetles that can infest bins. These traps are hollow "plastic" tubes with a series of downward sloping holes all along the sides. The top is a flat cap. The bottom is a pointed piece that screws in place. Insects crawling into the tube through the small holes can accumulate at the pointed end of the trap. A nylon line should be securely attached for easy retrieval from the grain mass.

These traps can be inserted in the grain using a long pole with a cup device on the end. This device is easily made using a paint roller extension handle and some "PVC"plumbing fixtures. Attach to the extension handle, a PVC "reducer" that has one side just about the size of the screw on the end of the extension handle while the other side is large enough to serve as a cup over the end of the trap. This will allow you to push the trap into the grain from an inspection hatch, internal ladder, or some other safe place, thus avoiding having to cross the grain surface.

The trap is retrieved using a nylon line which was attached to the trap before it was placed in the grain, and tied off to some convenient location in the bin. The line will also serve to keep traps from being sucked into the grain stream in case they are forgotten at unloading time.

How many traps are needed? The greater the number of trap samples, the greater the probability of detecting insect activity. For grain, the standard is 4 to 5, certainly now fewer than three, per round bin.

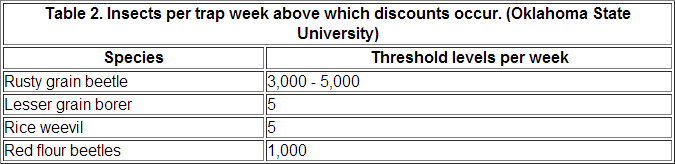

Thresholds for a one-week sampling period vary with species sampled and the grain Temperature (Table 2). If grain temperature is below 60o F, the numbers in Table 2. indicate a very high population size.

Economics of Pest Control

The constant fluctuation of grain prices and costs of insecticides, as well as attitudes of local buyers, make it impossible to set a specific cost-return value for treatment of stored grain. In Kentucky, most often the cost of an insect infestation in stored grain is that the buyer pays less for that grain. Find out what local buyers dock for infested grain, and compute the cost of treatment to see which provides the best return. If grain is plentiful, buyers can be choosy so the dock for infested grain will be greater. In that case, treating infested grain is usually more cost effective. On the other hand, if grain is scarce, buyers may not dock at all for insects, so treatment would be cost prohibitive. It is never cost effective to treat non-infested grain.

Insecticides and Fumigants

Labeling and application regulations for fumigants and grain protectants are subject to change. To insure that information on these products is as current as possible lists of insecticides and fumigants for use in stored grain may be found in the appropriate annually revised commodity publications as follows:

ENT-13 Insecticide Recommendations for Soybean

ENT-16 Insecticide Recommendations for Field Corn

ENT-24 Insecticide Recommendations for Grain Sorghum (Milo)

ENT-47 Insecticide Recommendations for Small Grains (Barley, Oats, Wheat)

You may view these publications on line at: http://pest.ca.uky.edu/EXT/Recs/welcomerecs.html

Do not use malathion as residual treatment for empty bins, a protectant or ‘capout' treatment. Malathion labeling is being removed for stored grain. More importantly, several stored grain pests have exhibited tolerance to malathion.

Common Stored Grain Insects In Kentucky

A variety of insects can be found in Kentucky stored grain. Fortunately, only a few are responsible for most problems and most of them are relatively easy to identify. These pests are divided into two main groups the beetles and the caterpillars. The caterpillars are easily identified. However, stored grain beetle pests are quite small so a hand lens is needed to see enough features to determine if important pests are present.

Indian meal moth (above) is one of the most common and troublesome insects attacking most any type of stored grain. The adult is a moth with a coppery color on the outer two-thirds of the front wings. Presence of the adult, though not damaging, can indicate the presence of an infestation. The moths lay eggs on the gain surface. These eggs hatch into the caterpillars (worms) that cause damage. The worm is about ½" long when grown and whitish in color. IMM rarely causes extensive kernel damage, or grain discount at the time of sale. However, the larvae may completely web over the grain surface, thus preventing proper air movement for aeration and fumigation and causing surface grain moisture accumulation and "top crusting".

The most common beetles, often called "bran bugs" (pictured above), do not feed on whole sound kernels, but rather live on broken kernels, dust, and trash. There are two major types in Kentucky the "flour beetles" and the Cryptolestes beetles. These insects are likely to be found in every bin of stored grain in the state. The real question is are there enough to do and damage?

There are two flour beetles (pictured above), Red flour beetle and the Confused flour beetle. They look very much alike and are separated by examination of the last three segments on the antennae. However, these beetles are usually found together in an infestation and do about the same damage.

There are also two common Cryptolestes beetles. They are the flat grain beetle and the rusty grain beetle. They look very much alike and are about one-half the size of the flour beetles. They are very flat in appearance and have beaded antennae about one-half as long as the body. They are often found in mixed infestations with flour beetles and do a similar type damage, but it takes two to three times as many flat/rusty grain beetles to do the same amount of damage as the flour beetles.

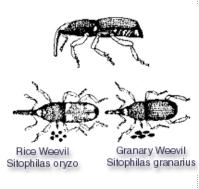

Perhaps the two most dangerous insects in Kentucky stored grain are the "weevils", which are usually found in corn, and the lesser grain borer which is more often a problem in wheat.

The weevils (pictured above) are relatively easy to tell apart from other insects because of their "snout". These are long, thin, downward curving mouth parts sticking out from the head.

The lesser grain borer also has a distinctive shape. However, it is the overall look of this insect that allows the identification. Lesser grain borer are very cylindrical in shape and both the head and tail end look very flat. It is kind of like using a straw to take a plug out of an apple only much smaller.

Both the weevils and lesser grain borer are primary feeders. They both feed on whole, sound kernels and their young develop inside the kernel. Infestations of these insects are very important.

Most other insect pests are secondary feeders. They cannot feed on whole sound kernels, but rather do their damage by their presence, and the heat and moisture they generate.

There are a large number of other insects that can infest stored grain. You may find information, pictures of these insects and links to other storage sites at: IPM in Kentucky Farm Stored Grain

REFERENCES

- Oklahoma State University, Stored Grain Management in Oklahoma - F7180.

- Pennsylvania State University, Weevils on Stored Grain - SG 13.

Issued: 6/03

Revised: 7/09

CAUTION! Pesticide recommendations in this publication are registered for use in Kentucky, USA ONLY! The use of some products may not be legal in your state or country. Please check with your local county agent or regulatory official before using any pesticide mentioned in this publication.

Of course, ALWAYS READ AND FOLLOW LABEL DIRECTIONS FOR SAFE USE OF ANY PESTICIDE!

Images: University of Kentucky Entomology