Insecticide Dust Bags for Cattle Insect Control

ENTFACT-515: Insecticide Dust Bags for Cattle Insect Control | Download PDF

by Lee Townsend, Extension Entomologist

F. W. Knapp, Professor of Entomology, Emeritus

University of Kentucky College of Agriculture

Face flies, horn flies, and lice are major pests that cause millions of dollars of losses each year. They can be controlled using insecticide sprays, mists, or fogs but these applications usually require that the producer bring cattle to a central location, a practice that is time consuming and expensive. Many producers like to use self-application devices and most are quite familiar with back rubbers or back oilers that can be purchased ready-to-use or made from materials found on the farm. These devices are very effective for controlling some insects when used properly but require frequent servicing with insecticide liquid. In addition, they may not be very effective in controlling face flies.

Horn flies and face flies are the two major pests that attack pastured cattle. Horn flies usually are easy to control but face flies are not. Research at the University of Kentucky, and elsewhere, has shown that forced-use dust bags give excellent control of both of these insects along with horse flies, deer flies, and mosquitoes. Winter cattle pests, such as lice, also can be controlled effectively with the proper use of dust bags.

Dust bags not only give effective insect control but are very convenient to use since they require much less maintenance than back rubbers or back oilers. Some can hold up to 25 pounds of dust so the insecticide does not have to be replenished frequently. In addition, insecticidal dust formulations are very stable and do not have to be mixed for use as do most back rubber solutions. Dust bags are also less affected by weather. Heavy rains are kept out by canvas protective covers so dust stays dry and continues to flow.

Types of Dust bags

There are several types of commercially available dust bags that are well-constructed and easy to use. Most are sold in kits that contain a dust bag, a length of sturdy weather-resistant rope and two plastic covered packages of insecticide dust. Refill kits that contain only insecticide dust are also available.

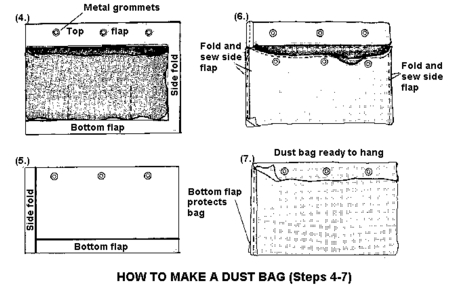

Most commercial dust bags are constructed with a burlap or nylon inner bag covered with a heavy canvas outer bag. They come in two basic shapes. Large flat, rectangular dust bags (about 3 feet x 2 feet) can be hung across gates or doorways. Conical or cylindrical butt-type dust bags are designed to be hung in loafing areas and other spots where cattle can butt them. Most commercial bags have three metal grommets or three heavy cloth loops arranged along the top of the bag to allow convenient hanging. These bags are easily refilled with insecticide dust, and if hung properly, will last for several seasons.

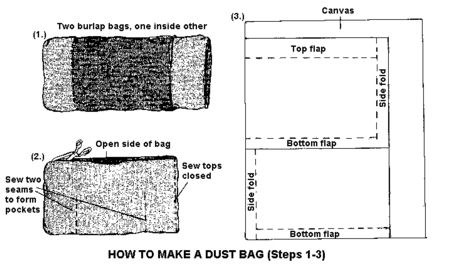

Dust bags can also be made from 21inch x 36-inch bags (new if possible). If you supply the bags, grommets, canvas and leather, anyone with an industrial sewing machine (shoe repair, tent and awning store) can quickly make a complete bag very inexpensively (see Figures 1 and 2 below).

Commercial and homemade dust bags will last longer if they are cared for properly. If you don't use dust bags during the winter, hang them in a dry protected location so they will not pick up moisture and rot during storage.

How To Use Dust bags

Dust bags give very good insect control when they are placed where cattle have to use them every day. The most effective way to set up a forced-use dust bag is to isolate the water source and force the cattle to pass under the dust bags to drink. This method is very effective since cattle go to water at least once a day. If you water your cattle out of tanks, it is very convenient to set up forced-use dust bags. The tank can be enclosed with a strong wooden fence, allowing at least 12 feet of room around the tank so animals can drink comfortably. Building the fence out of sturdy lumber and posts will ensure that it will last for a long time.

A portable enclosure can be constructed using steel posts and wooden or metal gates. Woven wire or barbed wire fencing can also be used to enclose the watering area. If this method is chosen, enclose a larger area to reduce the possibility of cattle backing or being pushed through the fence. Stress on the fencing can also be reduced by nailing "bump boards" about waist high all around the inside of the enclosure.

The openings into the area around the tank should only be about 3 feet wide. This will allow the entire opening to be covered with a large rectangular dust bag. Openings should be placed on opposite sides of the enclosures to allow cattle to enter and exit easily.

A concrete apron or heavy gravel placed around the tank will keep this area from becoming excessively muddy during wet weather. Whenever possible, place the tanks so that they will provide water for several pastures. This will reduce the labor needed to set up forced-use dust bags for all the pastures.

Many producers water their cattle out of ponds or lakes. It is still possible to set up forced-use dust bags in these situations. It is usually most practical to use woven wire or barbed wire to enclose the water source. Be sure to fence off enough area so that the cattle can easily drink without falling into the water. Damage to the banks of the pond or lake can be reduced by fencing off the entire pond or lake and restricting the area that the cattle are allowed to use. The banks in the drinking area can be stabilized using heavy gravel. Only one opening is necessary when using forced-use dust bags around ponds.

Many livestock producers do not want to spend the time and money necessary to construct a permanent fence around a pond or lake. Electric fencing can be used to enclose the area. When an electric fence is used, it is important to allow the cattle to become acquainted with the entrance to the watering area before hanging the dust bag. The entrance can be made more visible by hanging cloth flags on the wire leading to the opening or by outlining it with wooden gates set up on either side. After cattle become accustomed to using the opening, hang the dust bag. The animals will quickly learn to associate the dust bag with the opening leading to the water.

Hanging Dust bags

The success of forced-use dust bags depends largely on how they are hung. They should be hung so that they can swing freely. Attach strong, weather-resistant ropes in loops at each grommet or cloth loop and then tie the bag across the opening leading to water. Do not nail the bag to a wooden cross beam because this restricts the movement of the bag and will eventually tear out the grommets or cloth loops. In addition, it is much more difficult to adjust the height of the dust bags when they are nailed in place.

Often, dust bags are hung too high. Hang them low, about knee high, so that the cattle have to pick them up with their heads when they pass by. They must be hung low to give effective face fly control on small calves as well as on the adult animals.

After hanging dust bags, watch the cattle as they use them. If they are able to avoid the bags with their heads, lower the bag so that it treats their faces with insecticide dust as they pass through. Use your imagination and some "cow psychology."

Semi-Forced-Use and Voluntary-Use Dust bags

Even when it is impractical to isolate all the water sources in a pasture, it is still possible to use dust bags effectively. Salt and mineral stations can be fenced off so that the cattle have to pass through a dust bag. This type of an arrangement works better if the enclosed area also includes a source of good clean water.

Large flat dust bags hung on the front of mineral feeders will also aid in insect control. Make sure it covers the entire opening of the feeder so that the cattle have to bump the bag when feeding on the mineral. Mineral feeders that are at least 4 feet deep work best since the cattle will treat their faces and their backs while eating the salt or mineral.

Voluntary-use of dust bags will also aid in the control of cattle insect pests. Butt bags hung in loafing areas will be used by cattle if they are hung about waist height. They should always be used in conjunction with other types of insect control. Back rubbers hung in these areas will give effective control, especially when strips of cloth are tied at 4 to 6 inch intervals along the length of the back rubber to help apply insecticide to the faces of the animals using it. Insecticide sprays may have to be used periodically to keep fly populations at manageable levels when voluntary-use methods are used.

Dust bags and other insect control devices should be continued all year around. This will provide control of lice in the winter in addition to fly control during the summer. Year around use of dust bags has the added advantage of keeping cattle familiar with them so they will use them more often.

Information on types of insecticide dusts to use can be found in publications ENT-11, "Control of Beef Cattle Insects" or ENT-12, "Insect Control on Lactating Dairy Cows."

Issued: 6/08

Revised: 6/08

CAUTION! Pesticide recommendations in this publication are registered for use in Kentucky, USA ONLY! The use of some products may not be legal in your state or country. Please check with your local county agent or regulatory official before using any pesticide mentioned in this publication.

Of course, ALWAYS READ AND FOLLOW LABEL DIRECTIONS FOR SAFE USE OF ANY PESTICIDE!

Images: University of Kentucky Entomology