Powderpost Beetles and the Spirits Industry

ENTFACT-650: Powderpost Beetles and the Spirits Industry | Download PDF

By Michael F. Potter, Extension Entomologist

Powderpost beetles are a growing concern for distillers in Kentucky. Similar to termites, the beetles infest wood and are a particular problem in rickhouses. Over time, the pests can seriously damage posts, beams, rails and flooring, contributing to a loss of structural support. Recent incidents involving rickhouse collapses have heightened concerns about worker safety and the role that these beetles might be playing. This article will help the spirits industry understand the pests better, in order to remediate and prevent infestations.

What are Powderpost Beetles?

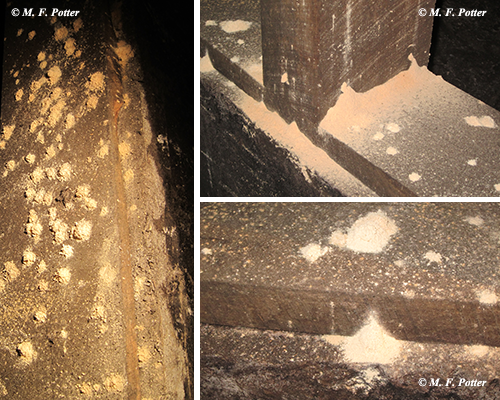

Powderpost beetles are small, 1/8-1/2 inch long insects that reduce wood to a flour-like powder. The grub-like larvae make narrow, meandering tunnels in wood as they feed. Newly emerged adult beetles mate and lay eggs on the wood surface. Eggs hatch into tiny larvae that bore in the wood, emerging as adults some years later. People typically discover infestations after noticing powder, accompanied by small, round ‘shot holes’ in the wood surface. These are exit holes where adult beetles have chewed out of the wood after completing their development. Powder sifting from the holes often accumulates in small piles below, or may be forced upward from flooring and horizontal surfaces. Since the adults are somewhat inconspicuous and active mainly at night, you are more likely to see the resulting holes and powder than the beetles themselves.

Powderpost beetles tunnel through wood, producing fine powder and small exit holes.

There are different types of powderpost beetles. The most common variety found in rickhouses are called anobiid (ano·by·id) powderpost beetles. Anobiids are convex, brownish beetles that attack oak, poplar, and other hardwoods, as well as softwoods such as pine. Consequently, all structural wood in the building is susceptible to attack. Infestation of barrels has not been reported. This might be due to the barrel staves being comprised mostly of heartwood (beetles tend to have a preference for sapwood) — or it could be due to the relative newness of the staves, or alcohol seepage into the wood.¹

Anobiid powderpost beetle (the holes are where beetles emerge from the wood)

In nature, anobiids dwell in dead tree limbs or trunk scars. Although beetles at some point may have flown in from outdoors, most rickhouse infestations likely originated years ago and, left unchecked, have continued to propagate over time.

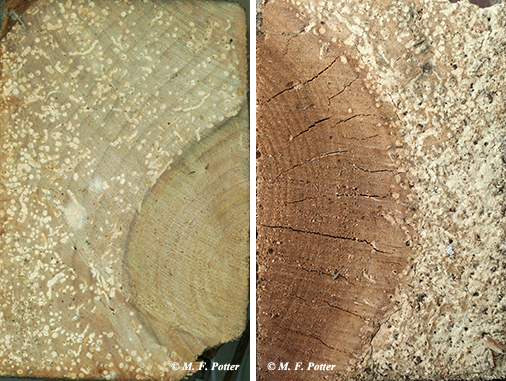

Adult beetles emerge from infested wood during spring and summer, especially May-July. Soon after emerging, the adults (which only live 3-4 weeks) mate and lay eggs. Females often lay their eggs on the same piece of wood from which they emerged. Eggs are laid singly (about 25-30 per female) on roughened surfaces or within crevices, joints, and old exit holes. They hatch in a few weeks and the tiny grub-like larvae chew directly into the wood. The larvae prefer to feed in the sapwood, but may also tunnel into heartwood. As the larvae grow, the wood is reduced to powder consisting of digested wood fragments and tiny pellets excreted as the larvae feed. Rubbed between the fingers, the powder feels smooth when the source is oak or another hardwood, but somewhat gritty when the beetles feed on pine.

Larvae prefer to tunnel in sapwood more than heartwood.

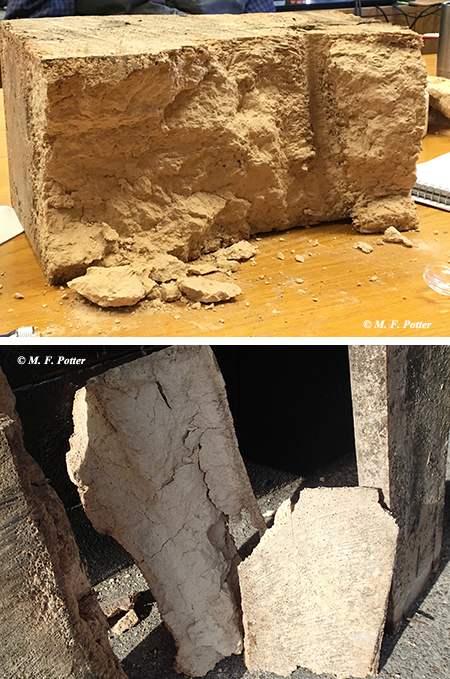

Development progresses slowly, averaging about three years from egg to adult. Depending on prevailing conditions, the lifecycle can range from one to five years. Assuming conditions remain suitable, reinfestation continues year after year with multiple generations overlapping within the wood. Over time, the beetles can seriously damage posts, rails, flooring, and other components.

Beetle damage in a rickhouse. It took many years to reach this point.

Conditions Suitable for Infestation

Moisture is the most crucial environmental factor affecting the destructive potential of this pest. Anobiids prefer damp wood with a 13 to 30% moisture content (MC), which is required for development. High moisture is especially crucial for survival of the tiny, newly hatched larvae before they penetrate the wood surface. Besides needing wood moisture for larval development, high humidity is essential for egg hatch. At 65-95% relative humidity (RH), the majority of eggs successfully hatch; below 60% RH, hatching drops to zero.

Because of their high moisture requirement, powderpost beetle infestations are most severe in rickhouses that are damp and poorly ventilated. Poorly drained sites are especially vulnerable, and the damage is usually worse near ground level. Higher in the building, moisture and humidity tend to be lower; therefore, infestation occurs less often above about the third floor level. Another reason damage tends to be worse on lower floors involves temperature. Optimal temperature for beetle development is about 60-75⁰F. Higher in the rickhouse, temperature fluctuations are more extreme and less favorable for beetle development. High temperatures also promote drying of the wood.

Anobiid powderpost beetles can digest cellulose (the hard, structural component of wood), and are less dependent on other nutrients that decline over time. This enables them to infest wood regardless of age. In Europe, the beetles have persisted in buildings that are several hundred years old. Active infestations also have been found in century-old rickhouses in Kentucky. The beetles may actually prefer older wood. Observations in Britain suggest that oak timbers, in particular, are seldom attacked until they are cut and in service for 60 years. In the U.S., softwood timbers in dwellings are rarely infested before at least 10 years. Along with the lengthy maturation time of the beetles, this could help explain why fewer problems are noticed in rickhouses built more recently. Although it takes years for infestations to become established, damage often materializes thereafter in a relatively brief period.

Confirming an Infestation

Powderpost beetle infestations sometimes die out of their own accord. Therefore, it is useful to know whether the infestation is active before taking action and expending time and resources. Active infestations usually have powder the color of freshly sawn wood streaming from or accumulating near exit holes. Old, abandoned holes often have no accompanying powder and will have taken on the aged appearance of the surrounding wood. If the powder appears caked, or is covered with dust, webbing, or debris, the damage probably is old. Additional measures may be needed to distinguish new powder from old, which is sometimes dislodged out of larval feeding galleries by vibrations. To help determine if infestations are still active, existing powder can be removed with a broom, vacuum, etc. to see if it reappears. Since beetles typically emerge in spring or summer, in colder months it may be necessary to wait until the following year to determine if new powder forms.

Old emergence holes suggesting infestation is no longer active

Removing existing powder helps determine infestation status

Similar-looking beetles that are not powderpost beetles also occur in rickhouses. A common example are fungus beetles. Fungus beetles scavenge on surface molds growing in damp conditions, but do not bore into wood or cause damage. Long-established powderpost beetle infestations are also sometimes accompanied by minute, pin-size holes and powder on wood surfaces. Smaller than beetle emergence holes, these are usually from tiny (beneficial) wasps that have pierced the wood surface in order to lay their eggs on the developing larvae.

Managing Infestations

The following measures will help control and prevent powderpost beetles in rickhouses. It is often best to employ multiple methods when conditions allow.

Reducing Moisture & Humidity – Anobiids have high moisture and humidity requirements for survival. When possible, it is advisable to reduce dampness by increasing ventilation. During spring/summer, wood moisture content below 15 percent and relative humidity below 60 percent is unsuitable for beetle development. Moisture and relative humidity meters are useful tools for taking measurements and predicting the potential for sustained infestation. To further reduce dampness, consideration should be given to improving drainage. In severe cases, it might also be prudent to install a ground vapor barrier (e.g., 8 mil polyethylene sheeting) to reduce moisture evaporation from soil and condensation on wood surfaces.

Moisture meters are useful for assessing beetle-conducive conditions

Wood Replacement/Structural Assessment – If infestation appears limited to a few posts, rails, or sections of wood, one option is to remove and replace them. This is especially prudent when signs of infestation are substantial, and there may be diminished structural support. Wood that has been significantly damaged by beetles may sound dull or hollow when struck with a hammer. A pick hammer (like those used by geologists) is especially handy because it combines the use of sound and the pick end to probe the wood member. Probing beetle-damaged wood with an awl or knife can also help reveal softness and deterioration. Areas of concern can then be evaluated further using more advanced tools such as a resistance microdrill.² Beetle holes and powder in wood elements not replaced should be sealed and the powder removed (by brushing, pressure washing, etc.) so that old damage will not be mistaken for new. The area can then be inspected periodically to ensure that activity has ceased.

Substantial powder warrants further investigation. A pick hammer is useful when surveying for deterioration

Borate Insecticide Treatment – Various insecticides are available to treat beetle-infested wood. The most widely used are called borates, which have favorable characteristics. Borates are minerals mined from deposits in the earth. They are an ingredient in many household products, including borax laundry powder. The form used to protect wood (disodium octaborate tetrahydrate) is lethal to wood-boring beetles, termites and decay fungi.

Borate insecticides are safe, virtually odorless, and often retain their protective properties for the serviceable life of the wood. They also have the ability to diffuse inward; the damper the wood, the deeper they penetrate— making them ideally suited for treating moisture-loving anobiid powderpost beetles. Even at lesser wood moisture levels (<15%), effective concentrations penetrate deeply enough to kill newly hatched larvae before they tunnel inward. While older larvae already within wood may succumb as well, the greatest effect/benefit from remedial borate treatment is breaking the cycle of reinfestation.

Several rickhouses in Kentucky are currently being treated with borate insecticides, primarily Bora-Care and Tim-bor.³ Wood is sprayed at low pressure to the point of surface saturation with a backpack or larger capacity sprayer. To eliminate concerns from overspray, barrels are removed from treated areas or protected with plastic sheeting. Borates are being applied remedially to beetle-infested wood, and to replacement lumber used for repairs. Another trend is to treat all wood members (infested or not) up to about the third level, unless evidence of infestation extends higher in the building. Before treatment, dust and accumulated debris is brushed or otherwise removed to allow the spray to better wet the wood surface. Borates are also being applied preventively to new rickhouses under construction. Prior to or during construction, lumber is sprayed, dipped, etc., affording protection against infestation for many years.

Treating a rickhouse with borates.

Is There Another Solution?

Questions arise about other methods for controlling powderpost beetles, such as heat treatment or fumigation. Unfortunately, neither approach is practical for rickhouses. Although all insects succumb at around 120-130°F, it would be hard to achieve such temperatures deep within all rickhouse timbers using current heating equipment. Fumigation is also problematic; today’s fumigants (e.g., sulfuryl fluoride) are less effective against wood-boring beetles than prior compounds such as methyl bromide. Fumigation or heat treatment also would be difficult logistically, since both methods would require sealing the entire rickhouse with tarps and removing all barrels.

Beetles in Pallet Warehouses

Some distillers also worry that powderpost beetles will damage wood pallets on which barrels are stacked and stored — potentially leading to collapse. Anobiid beetles seldom if ever infest pallets, but damage can occur from another powderpost beetle group, known as lyctids. The small, elongate beetles sometimes infest newly constructed oak pallets (pine pallets, though less durable, are immune from attack). As with rickhouses, there have been no reports of the beetles infesting barrels in pallet warehouses. Avoidance of barrels by lyctids is probably due to their preference for sapwood (barrel staves being comprised mostly of heartwood), and alcohol seepage into the wood.

Pallet storage of barrels in a warehouse

Lyctid powderpost beetle near an exit hole (photo on right shows powder on a pallet)

Unlike anobiids, lyctid powderpost beetles seldom infest wood older than about 3-5 years. This is because the beetles depend on starch, which declines as wood ages. If the starch content of wood is insufficient, the beetles will not use it for egg laying. Low starch also makes it harder for the larvae to complete their development.⁴ If a warehouse pallet is infested, the beetles were probably in the wood before the pallet was delivered. Lyctid powder feels like fine talc and often accumulates in small piles near pinhead-size emergence holes. Damage is often limited to a single board or stringer, which would not necessarily affect the pallet’s structural support.

Since lyctid infestations are self-limiting, spraying pallets with an insecticide probably is not necessary. If infestation is still a concern, newly fabricated pallets could be kiln-dried and held in a beetle free indoor location before delivery. Another option would be to transition to plastic pallets, which are increasingly being used by other industries.

Summary

Powderpost beetles are a significant contributor to the deterioration of wood. While it takes years for the pests to inflict serious damage, it is important to detect problems before structural support and safety are impacted. Distillers should learn to recognize the signs of infestation (powder, exit holes), and periodically inspect buildings where barrels are stored. Modifying conditions favorable to beetle development (high moisture, relative humidity), replacing damaged timbers, and utilizing wood protectants (e.g. borates) will further help to minimize potential problems.

___________________

¹ Although powderpost beetles seldom if ever attack barrels, other wood-boring insects can, especially before logs are made into staves. Recent findings in Kentucky suggest the beetle responsible for most ‘worm’ holes causing barrel leakage is probably the oak timberworm, Arrenodes minutus. Additional information about this pest will be forthcoming on the University of Kentucky Entomology Department website.

² https://inspectapedia.com/structure/Micro_Drilling_Wood_Test_Procedure.php

³ Bora-Care is formulated with ethylene glycol and diluted in water (1:1), resulting in a 20% end-use solution. Tim-Bor is a powder that when diluted in water generally makes a 10% solution. Although Bora-Care costs more, the more concentrated solution allows for more borate to be applied from a single application.

⁴ Unlike anobiids, lyctids are far less dependent on moisture. Larvae can persist in wood with a moisture content below 10%, which is common in warehouses and other temperature-controlled environments.

CAUTION: Some pesticides mentioned in this publication may not be legal in your area of the country. If in doubt, please consult your local cooperative extension service or regulatory agency. ALWAYS READ AND FOLLOW LABEL DIRECTIONS FOR THE PRODUCT YOU ARE USING.

Please note that content and photos in this publication are copyrighted material and may not be copied or downloaded without permission of the Department of Entomology, University of Kentucky.

Michael F. Potter is an entomologist and Provost’s Distinguished Service Professor at the University of Kentucky.